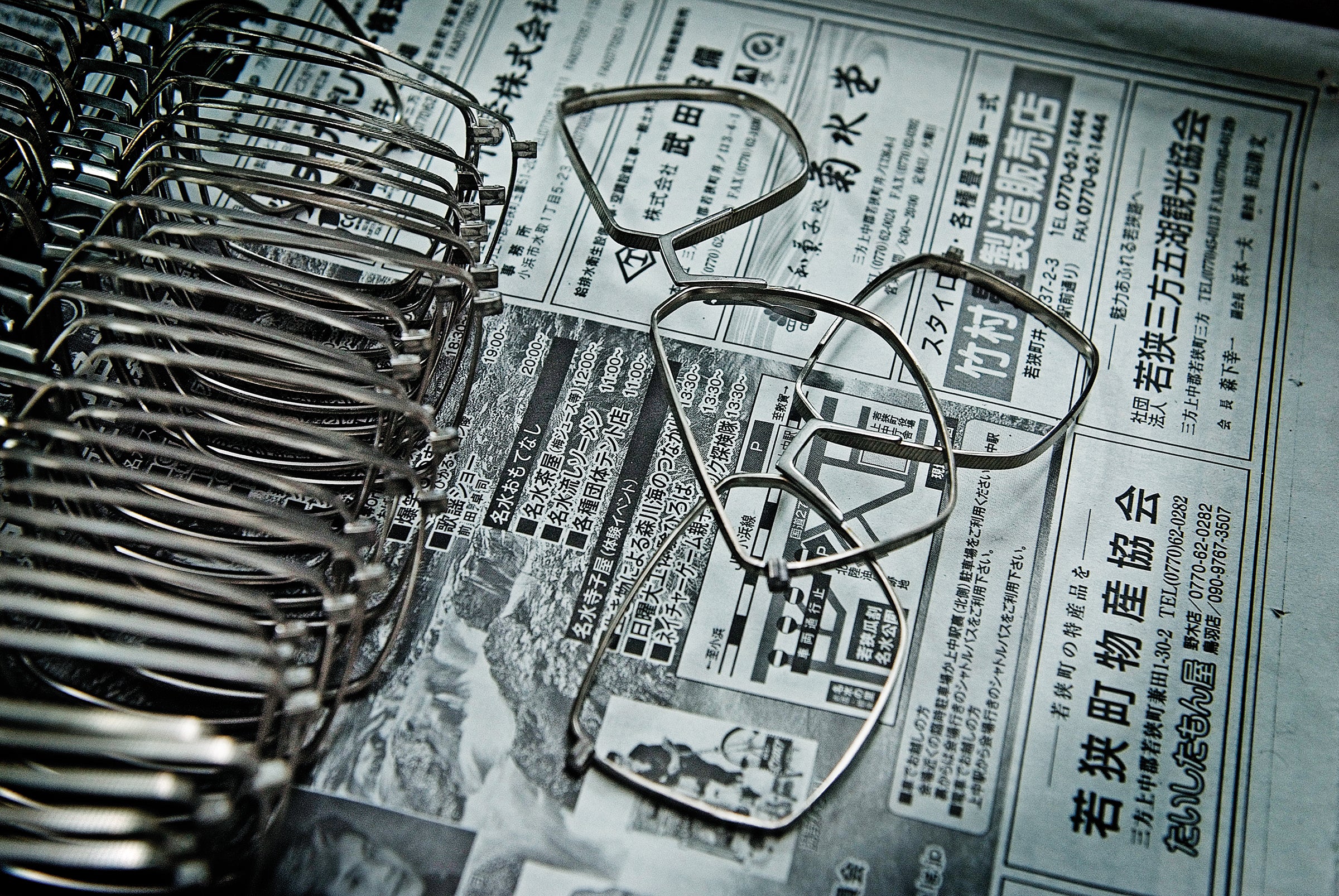

WHAT DOES IT TAKE TO CREATE A SINGLE DITA FRAME?

QUALITY MATERIALS

QUALITY TITANIUM • JAPANESE ACETATE

CREATING A SINGLE DITA FRAME CAN TAKE AS MANY AS 350 SEPARATE PRODUCTION STEPS OVER 8 MONTHS. OUR MANUFACTURING PROCESS DELICATELY BALANCES TRADITIONAL AND MODERN PRODUCTION TECHNIQUES AND TECHNOLOGIES CAREFULLY SELECTED AT EACH STAGE TO GENERATE THE BEST RESULT. A PERFECT EXAMPLE OF DITA’S UNCOMPROMISING PRODUCTION PHILOSOPHY IS THE WAY IN WHICH WE POLISH OUR ACETATE FRAMES. WE MANUFACTURE IN SOME OF THE WORLD’S OLDEST AND MOST RESPECTED EYEWEAR FACTORIES, INCLUDING FACTORIES OWNED BY THE SAME FAMILIES FOR GENERATIONS.

CRAFTSMEN AND MASTER CRAFTSMEN CONTINUOUSLY EVALUATE EACH FRAMES' SHAPE, FIT, AND FINISH THROUGHOUT THE PRODUCTION PROCESS. RUNNING THEIR HANDS OVER THE FRAMES' SURFACES IN SEARCH OF THE SLIGHTEST IMPERFECTION OR IMBALANCE, THEY WILL CONTINUE SHAPING AND POLISHING UNTIL THEY DETERMINE THAT THE FINISHED PRODUCT MEETS DITA'S EXCEEDINGLY HIGH QUALITY STANDARDS.

DISCOVER MORE

DITA HERITAGE

FOUNDED IN 1995 DITA REINVENTED EYEWEAR BY CREATING A DISCREET LUXURY WITH PRODUCT RANGING FROM BOLD CHARACTERFRAMES TO NEW INTERPRETATIONS OF TIMELESS SHAPES THROUGH INNOVATIVE TECHNOLOGY.

BRAND HERITAGE